Taper A taper may be defined as a uniform increase or decrease in diameter of a piece of work measured along its length. Taper turning methods

1. Form tool method

2. Compound rest method

3. Tailstock set over method

4. Taper turning attachment method

5. Combined feed method

(i) Form tool method

A broad nose tool is ground to the required length and angle. It is set on the work by providing feed to the cross-slide. When the tool is fed into the work at right angles to the lathe axis, a tapered surface is generated. This method is limited to turn short lengths of taper only. The length of the taper is shorter than the length of the cutting edge. Less feed is given as the entire cutting edge will be in contact with the work.

(ii) Compound rest method

The compound rest of the lathe is attached to a circular base graduated in degrees, which may be swivelled and clamped at any desired angle. The angle of taper is calculated using the formula: where D = Larger diameter d = Smaller diameter l = Length of the taper Ɵ = Half taper angle The compound rest is swivelled to the angle calculated as above and clamped. Feed is given to the compound slide to generate the required taper.

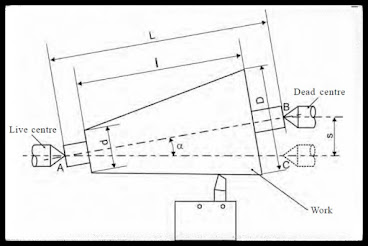

(iii) Tailstock set over method

Turning taper by the set over method is done by shifting the axis of rotation of the workpiece at an angle to the lathe axis and feeding the tool parallel to the lathe axis. The construction of tailstock is designed to have two parts namely the base and the body. The base is fitted on the bed guide ways and the body having the dead centre can be moved at cross to shift the lathe axis. The amount of set over (s) can be calculated as follows:

The dead centre is suitably shifted from its original position to the calculated distance. The work is held between centres and longitudinal feed is given by the carriage to generate the taper. The advantage of this method is that the taper can be turned to the entire length of the work. Taper threads can also be cut by this method. The amount of set over being limited, this method is suitable for turning small tapers (approx. unto 8°). Internal tapers cannot be done by this method.

(iv) Taper turning by an attachment

The taper attachment consists of a bracket which is attached to the rear end of the lathe bed. It supports a guide bar pivoted at the centre. The bar having graduation in degrees may be swivelled on either side of the zero graduation and set at the desired angle to the lathe axis. A guide block is mounted on the guide bar and slides on it. The cross slide is made free from its screw by removing the binder screw. The rear end of the cross slide is tightened with the guide block by means of a bolt. When the longitudinal feed is engaged, the tool mounted on the cross slide will follow the angular path as the guide block will slide on the guide bar set at an angle of the lathe axis. The depth of cut is provided by the compound slide which is set parallel to the cross-slide.

The advantage of this method is that long tapers can be machined. As power feed can be employed, the work is completed at a shorter time. The disadvantage of this method is that internal tapers cannot be machined.

No comments:

Post a Comment