Rests

A rest is a mechanical device to support a long slender workpiece when it is turned between centres or by a chuck.

It is placed at some intermediate point to prevent the workpiece from bending due to its own weight and vibrations setup due to the cutting force.

There are two different types of rests

1. Steady rest

2. Follower rest

Steady rest

Steady rest is made of cast iron. It may be made to slide on the lathe bed ways and clamped at any desired position where the workpiece needs support. It has three jaws. These jaws can be adjusted according to the diameter of the work. One or more steady rests may be used to support the free end of a long work.

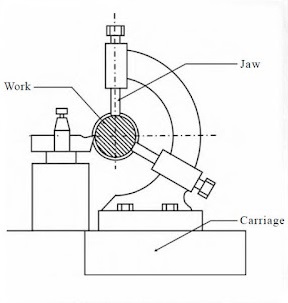

Follower rest

It consists of a ‘C’ like casting having two adjustable jaws to support the workpiece. The rest is bolted to the back end of the carriage. During machining, it supports the work and moves with the carriage. So, it follows the tool to give continuous support to the work to be able to machine along the entire length of the work.

No comments:

Post a Comment