This is the most widely used work holding device in lathe

Work can be tight rigidly and easily by loosening or tightening the jaws of the chuck by using a chuck key.

Different types of chuck available are:

Four jaw independent chuck

Three jaw universal or self centring chuck

Combination chuck

Magnetic chuck

Collet chuck

Air or hydraulic operated chuck

Drill chuck

Four jaw independent chuck

This chuck has four jaws and each of which can be tightened independently by its screw.

It can hold work pieces other than round section also.

This type of chuck is particularly used in the setting up of heavy and irregular shaped work pieces.

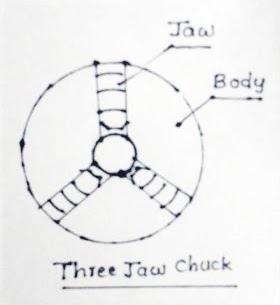

Three Jaw Chuck

Three jaws and three square slots are provided on the circumference of the body. All jaws can be moved simultaneously by rotating any one of the key slot

Speedy centring of the work piece is possible

It cannot hold heavy work pieces as it is not rigid clamping as four jaw chuck. A scroll plate is used to move the jaws simultaneously.

Combination chuck

This chuck can be used both as an independent and self centring chuck.

Magnetic chuck

This chuck is used for holding very thin work pieces made of magnetic materials which cannot be held in an ordinary chuck. The holding power is obtained by an electric or permanent magnet placed within the chuck.

Collet chuck

Collet chucks are used for holding bar stock in production work where quick setting and accurate centring is needed. The body of the chuck has a taper bore into which split collets are fitted. This collet can be drawn in pus out by a lever mechanism to tight or loose the work piece.

Air or Hydraulic operated chuck

In this chuck jaws are opened or closed by hydraulic or pneumatic actuators. This fast and reliable clamping method used in mass production work.

Drill chuck

Drill chuck is used in lathe for drilling and other related operations. It has self centring jaws and is operated by chuck key or by hand. The chuck is fixed into the tapered bore of the tailstock spindle.

No comments:

Post a Comment